conclusion of poldi hardness test|Poldi Impact Hardness testing Hardness Tester : sourcing Poldi hardness test. The Poldi hardness tester is one of the portable hardness testers. The indentation is obtained on the test surface by striking a blow on the ball which also produces . Para quejas, reclamaciones o si desea ponerse en contacto .

{plog:ftitle_list}

webOmniClouds offers you, through ExpressRoute, predictable, reliable, and high-speed, connections, allowing you to build applications that span local infrastructure and Azure .

POLDI hardness tester, as well as Brinell hardness tester, may be used for all forgeable iron and steel types with the exception of austenitic steels, e.g. steel with 25 % Ni, steel with 14 % Mn, corrosion- resistant Cr-Ni steel, non-magnetic steel, etc. Each calibrated steel piece can be .

Determination of the Brinell hardness. First, the ball impression diameter of the steel .Poldi Impact Hardness Tester enables to perform the impact test with the help of .The hammer type Poldi impact hardness tester is useful for simple and quick determination of Brinell hardness of metals such as steel, Cast Iron, Brass, Aluminium, Copper etc. Due to .Poldi hardness test. The Poldi hardness tester is one of the portable hardness testers. The indentation is obtained on the test surface by striking a blow on the ball which also produces .

Determination of the Brinell hardness. First, the ball impression diameter of the steel bar and the ball impression diameter of the test piece need to be found on the same page of the table. The .POLDI HARDENESS TESTER. Our “Poldi Hammer” is the most simple and most economical device for define hardness according to Brinell and determining tensile strength of engineering and tool steels, dies, forgings, railway material, .

Surface hardness imaging of a low

The accuracy of this hardness tester may very sometimes to the extent +/- 10% as against the more accurate table type standard Hardness testers. However, the Poldi Impact Hardness .Dynamic test methods relate hardness to the elastic response of a material, whereas the classical static indentation tests determine hardness in terms of plastic behavior. This chapter . Automated and non-contact imaging of surface hardness distribution using a single-shot LIBS mapping technique as a fast semi-quantitative method to conventional tactilet .

The Poldi hardness tester is an instrument for testing impact hardness. The size of an indentation on the sample to be tested is compared with the size of the indentation on a .Poldi Impact Hardness Tester enables to perform the impact test with the help of a hammer at workplaces, in workshops, at assembly sites or any other places. Brinell hardness and tensile strength can be seen in tables.The test made with the POLDI hardness tester shall be performed in the following way: Directions for use: Quenched steel ball with the diameter of 10 mm shall be put between the piece tested and calibrated steel bar of a defined tensile strength (check test piece). A single strong hammer stroke shall create ball impressions into the checkWhen the Poldi hardness tester uses the check test piece made of steel having the strength of 70 kg/mm 2, the deviation of the tensile strength converted from the Brinell hardness compared to the real tensile strength of steel, having the .

Hardness Tables:-Comparison tables for finding hardness Separate Tables for Steel, Cast iron, Brass Copper and Aluminum. ROCKWELL TESTING AIDS C-76A, Jyoti Colony, St. No.7, 100 Ft Road, Shahdara Delhi-110032 Ph : 011-22832463 , 65292646, : www.hardnesstesters.in E-mail : [email protected] , [email protected]

POLDI T Y PE H ARDN ESS T EST ER M ODEL : PH M APPLI CABI LI T Y The hammer type Poldi impact hardness tester is useful for simple and quick determination of Brinell hardness of metals such as steel, Cast Iron, Brass, Aluminium, Copper etc. Due to easy handling and manoeuverability, this tester is most suitable for testing heavy castings and other .Destructive testing:- Hardness testing (Rockwell/ Vickers) Hardness conversion number. 2) Brinell and Poldi hardness Test 3) Impact Test for Steel, Aluminum, Brass and Copper (Charpy/Izod) 4) Non Destructive testing : Dye Penetrant Test/ Magnetic Particle test/ Ultrasonic Test 5) Steps for Specimen Preparation for microscopic examination &When the common POLDI hardness tester uses the check test piece made of steel having the strength of 70 kg/mm², the deviation of the tensile strength converted from the Brinelll hardness compared to the real tensile strength in case of steel having the strength of 50-100 kg/mm² is maximum + 3 °/o , in case of milder types of iron and steel and steel having the strength of 100 .Find here Poldi Hardness Tester, Poldi Hardness Testing Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Poldi Hardness Tester, Poldi Hardness Testing Machine across India.

(III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper. #ASTM A833 #ASTM E10 #ASTM E110 #ASTM E114 #ASTM A370 #SA370 #ASME #PWHTStandard Practice for Indentation #hardness of Metallic Materials by Comparison Hard.

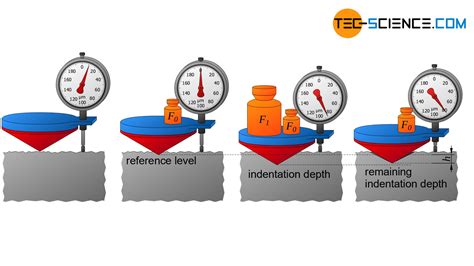

Poldi Impact Hardness Tester enables to perform the impact test with the help of a hammer at workplaces, in workshops, at assembly sites or any other places. Brinell hardness and tensile strength can be seen in tables. The test made with the POLDI hardness tester shall be performed in the following way: Directions for use: Quenched steel ball with the diameter of 10 .The hammer type Poldi hardness tester or Poldi hardness testing machine is suitable for measuring the Brinell Hardness of steel cast iron brass Aluminum copper etc. The Poldi hardness tester is useful to test part where branch type model is not useful. This type of machine is most ideal and simple for foundries workshop engineering colleges .The Poldi hardness tester is an instrument for testing impact hardness. The size of an indentation on the sample to be tested is compared with the size of the indentation on a reference Standard. In a similar way to the Brinell hardness test, the penetration depth is measured on both the test piece and the reference sample.The Leeb hardness test is explained in ASTM A956 and ISO 16859 standards as a dynamic method to check the hardness of metallic material. . Conclusion. In this blog, Leebs hardness method is completely explained for you to judge whether to use it or not for measuring the hardness of any object. To learn more about the Leeb Hardness test or .

DIRECTIONS FOR USE OF POLDI HARDNESS TESTER MODEL “NP”: Insert the tapered end of the standard test bar after cleaning into the space provided between the ball and the plunger and slide it further beyond the tapered position. The test bat will thus be firmly gripped between the ball and the plunger pressed by a spring.

The Brinell hardness of the test bar employed should align within a ±10% margin of the anticipated hardness of the test part and should be of a similar material type. Test Method In practice, the A833 standard procedure commences with the assembly of the test bar into the apparatus, ensuring adequate spacing to prevent interference with .Reflection Report Title: Poldi Hardness Test Submitted By: Name: Aniket Dethe Roll no- MESYB113 Exam Seat no- S189013 Aim: To measure hardness of given material. Principle: 1. An indenter is pressed into the surface of the material to .

DIRECTIONS FOR USE OF POLDI HARDNESS TESTER MODEL “NP”: Insert the tapered end of the standard test bar after cleaning into the space provided between the ball and the plunger and slide it further beyond the tapered position. The test bat will thus be firmly gripped between the ball and the plunger pressed by a spring.It is impossible to define a single conversion method using different hardness test methods. That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us.

conclusion was drawn based on the obje ctive of the . kann die Aussagesicherheit bei der Härteprüfung mit dem Poldihammer verbessert werden.Reliability of statement by Poldi hardness test. A .

Hardness Testing Portable hardness tests are performed by using various types of hardness test methods such as portable Brinell hardness test, Leeb hardness test, Poldi hardness test, impact telebrineller hardness test, ultrasonic hardness test and several other proprietary hardness methods such as Asaki and Krautkramer. The following Hardness tests are .

Get Price Quote. Material : Steel, Cast Steel Vickers : 83,976 Probe Type : D/DC The D-2 is an advanced pocketable hardness tester distinguished by its high accuracy, wide measuring range, simplicity of operation & above all it is a really portable instrument operating on three pencil cells of size AA. It is suitable for testing the hardness of many materials more.Conclusion: The hardness test experiment was done using a Brinell and a Rockwell Testers. The data obtained was recorded and compared. The experimental and referenced values for each metal were compared. Table 2 showed that the percent differences for Rockwell Test were smaller than for the Brinell test. This concludes that the Rockwell test is .hardness test, except that it is done on a microscopic scale with higher precision instruments. The surface being tested generally requires a metallographic finish; the smaller the load used, . Discussion of your results and a conclusion. References ASM International, Hardness Testing, 2nd Edition, 06671G.We are renowned Suppliers of Hardness Testing Machines as well as Spare and Accessories such as Poldi Test Bars that is used as hardness test bars extensively. We use premium quality raw materials to manufacture these bars under rigid standards of quality by adhering to international standards. Our esteemed clients can avail

Poldi Hardness Tester. The hammer type Poldi Impact Hardness Tester is useful for simple and quick determination of Brinell hardness of metals such as steel, cast iron, brass, aluminium, copper etc. . copper etc. Due to its ease of handling and compactness, this tester is most suitable for testing heavy castings and other components. Our . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .

Poldi hardness test

Adrenalina! Relembre os melhores momentos das Provas de Fogo. REVELAÇÕES. Na Live Final, Biel descobre que não bateu recordes em A Fazenda 12. LIVE FINAL. Lipe é .

conclusion of poldi hardness test|Poldi Impact Hardness testing Hardness Tester